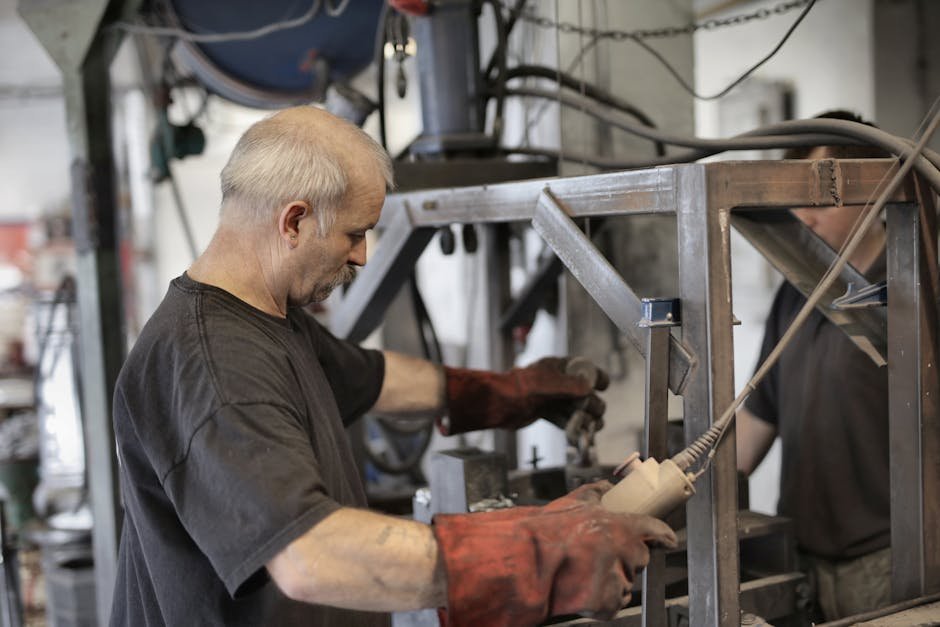

Preventative Roof Maintenance Tips for Manufacturing Industries

Understanding Preventative Roof Maintenance: An Introduction

Preventative roof maintenance is something you can't overlook, especially in manufacturing industries. It's all about taking care and spotting problems before they grow into disasters. Imagine your roof like a helmet. You wear a helmet to protect your head, right? The same goes for your building’s roof. It’s there to shield your entire operation from the elements. So, giving attention to roof maintenance is just smart business. Regular checks can catch leaks, damage, or wear and tear early. This way, fixing a small issue now can save you from a huge repair bill later. Think of it as regular health check-ups but for your building. This doesn't just save money; it keeps your operations smooth and uninterrupted by unexpected repairs or damage. In short, with preventative roof maintenance, you're staying one step ahead of potential problems, ensuring that your manufacturing processes continue to run efficiently and safely.

The Importance of Regular Roof Inspections

Regular roof inspections are key to preventing expensive repair jobs in the future. Think of it this way: catching a small issue early can save you a ton of money compared to dealing with a full-blown disaster later. For manufacturing industries, where facilities often cover vast areas with complex roofing systems, this becomes even more critical. A simple leak can lead to equipment damage, production halts, and safety hazards. By scheduling regular inspections, you're not just checking for damage; you're actively protecting your investment and ensuring that operations run smoothly. Ideally, roofs should be inspected at least twice a year, especially after extreme weather conditions. During these inspections, you're looking for signs of wear and tear, blockages in your drainage system, and any damage that might have been caused by external factors. Staying on top of these checks helps in extending your roof's lifespan and can significantly lower the costs associated with roofing issues. Remember, a little proactive care can go a long way in keeping your manufacturing facility safe and operational.

Identifying Common Roof Problems in Manufacturing Industries

In manufacturing industries, roofs take a beating. Recognizing issues early can save a ton of money and headache. Here's a rundown of common roof problems. First, leaks and moisture. This is roofing's enemy number one. It could be from rain, snow, or even your own HVAC systems. If you see water stains or drips, act fast. Next up, punctures. Workers, installations, and even wildlife can puncture your roof. Regular checks, especially after work has been done on the roof, are key. Third, pooling water. If water's hanging out on your roof for more than 48 hours after rain, you've got a problem. It can lead to leaks or worse. Also, watch out for poor installation and repairs. A bad job today means trouble tomorrow. It's worth paying for quality work up front. Lastly, lack of maintenance. This is a biggie. An "out of sight, out of mind" attitude can lead to serious damage. Regular inspection and care will keep your roof in top shape for years. So keep an eye out, fix issues early, and your manufacturing plant's roof will thank you.

Cleaning and Debris Removal as Preventative Measures

Cleaning your roof might not seem like a top priority, but for manufacturing industries, it's a crucial step in preventative maintenance. Let's break it down simply. Dirt, leaves, and other debris can accumulate on your roof. This might seem harmless at first, but over time, this build-up can lead to significant problems. Water can get trapped by the debris, leading to leaks and damage to your building's structure. Regular cleaning and debris removal are your first line of defense. It's not just about aesthetics; it's about preventing water damage, corrosion, and the breakdown of roofing materials. Think of it as a regular check-up for your roof to ensure it's healthy and strong, ready to protect your manufacturing operation from anything the weather throws at it. By keeping your roof clean and free of debris, you're taking a simple yet effective step towards avoiding costly repairs down the line.

The Role of Professional Roofing Services in Maintenance

Professional roofing services play a crucial part in maintaining the integrity of a manufacturing industry's roof. These experts come in and do more than just fix problems as they arise. They're the guardians of your roof, spotting small issues before they blow up into big, costly repairs. It's their job to know what to look for and where. They'll check for leaks, damage, and wear and tear that you might not spot with an untrained eye. Think of it like going to the doctor for a check-up, but for your roof. By catching problems early, they save you from the headache of downtime and expensive fixes. Plus, they can advise on the best materials and practices to prolong your roof's lifespan. Trusting your roof to professionals isn't just a smart move—it's essential for keeping your production rolling without unexpected interruptions.

Gutter Maintenance and Its Impact on Roof Longevity

Gutters play a crucial role in protecting your roof and the entire structure of your manufacturing facility. Their main job? To channel water away from your roof and building foundation. However, when gutters get clogged with leaves, twigs, and debris, they can't do their job. This can lead to water overflow, which might damage your roof, walls, and even the foundation of your building. So, keeping gutters clean is not just about avoiding water damage. It's also about increasing the lifespan of your roof.

Here's the thing – it's pretty straightforward. Clean gutters mean less risk of water buildup and less chance of water damage to your roof. Less water damage means your roof can last longer without needing repairs or replacement. Regular gutter maintenance prevents the buildup of debris, allowing water to flow freely away from your roof and building.

By scheduling regular gutter cleanings, especially after the fall and spring when debris tends to accumulate, you can prevent these issues. It's a simple, cost-effective way to extend the life of your roof and protect your facility. And remember, it’s way cheaper to maintain a gutter than to repair a damaged roof. So, don’t skip on gutter maintenance – it’s a key part of keeping your roof in top condition for years to come.

The Benefits of Timely Repairs and Maintenance

Keeping your roof in top shape isn't just about fixing leaks. Timely repairs and maintenance can save you a ton of money and headaches in the long run. Here's how. First, catching problems early means you're spending less on repairs. It's cheaper to fix a small issue now than a big one later. Next, a well-maintained roof lasts longer. This stretches out the time before you need a total replacement, giving you more bang for your buck. Also, downtime in manufacturing is a big no. A leaky roof can halt production, costing you more than just repair bills. Regular maintenance keeps your operations smooth. Plus, a sturdy roof protects your equipment and goods. Water damage from leaks can ruin materials and machinery, driving up costs. Lastly, energy efficiency. Gaps and cracks in your roof lead to higher heating and cooling bills. Sealing them up keeps your costs down. In simple terms, spending a bit on your roof now can save you a lot more down the road.

Implementing a Preventative Roof Maintenance Program

To keep your factory running smoothly, you've got to stay on top of your roof's health. Start a preventative roof maintenance program. This isn't complex. First, get your roof inspected twice a year. Once before the harsh weather kicks in and again after. Look for leaks, damage, or anything odd. Fix problems early to avoid big repairs later. Keep your roof clean. Leaves, debris, and the occasional bird's nest can add up, causing damage over time. Make sure your drainage is clear. Water pooling is bad news and can lead to leaks or even structural damage. Train your team to spot roof issues. If they see something, they say something. This way, you can deal with issues fast, keeping your operation running without a hitch. Simple steps, but they'll save you a lot of headaches and cash in the long run.

Tools and Equipment Needed for Effective Maintenance

In the world of manufacturing, your roof is like a hardworking hat—it's there to protect everything beneath it. But just as with any piece of equipment or machinery, it needs regular upkeep to perform at its best. The good news? You don't need an arsenal of complex tools to keep your roof in top shape. Let's break it down to the basics.

First off, get yourself a sturdy ladder. It's your gateway to reach the battleground—your roof. Next, you will absolutely need safety gear. This includes a harness, gloves, and non-slip boots because safety shouldn't be an afterthought; it's a priority.

Now, for the cleaning and inspection part. Arm yourself with a leaf blower or a soft-bristled brush. These are your weapons to combat leaves, debris, and whatever else has decided your roof is a nice place to settle. A caulking gun is next on your list. It's essential for sealing up any small gaps or cracks that you might find during your inspection.

Don't forget a good flashlight or a headlamp. Even during the day, there can be shadowy nooks and crannies that are easy to miss without a bright light.

Lastly, invest in a quality digital camera or use a smartphone with a good camera. Why? Because documenting the state of your roof before and after maintenance is crucial. It helps you monitor its condition over time and provide evidence if you ever need to make a warranty claim.

To sum up, keeping your roof in tip-top shape doesn't require you to break the bank on high-end tools. With just a few essentials—ladder, safety gear, leaf blower or brush, caulking gun, flashlight, and camera—you're well-equipped to tackle preventative maintenance like a pro. Stay safe up there, and remember, regular check-ups can save you a fortune in the long run.

Summary: Preserving Your Industrial Roof for Years to Come

Maintaining your industrial roof isn't just smart; it's essential for keeping operations smooth and avoiding costly disruptions. Think of your roof as your facility's top guard against nature's elements. With regular care, you can extend its lifespan significantly. It’s not complicated – check for leaks, blockages, or signs of wear and tear regularly. Fix problems early, before they grow. Keep the roof clean, and clear of debris. This means a yearly check-up and cleaning at least. Gutters and downspouts should be free-flowing to prevent water from pooling up. And don’t forget the surrounding trees; trim them to avoid branches scraping your roof or leaves clogging the drains. Last, know your roof's material and its specific needs because different types demand different care. A bit of effort can spare you massive future expenses. So, stay ahead with regular maintenance. This way, your industrial roof stays solid over your head, year after year.